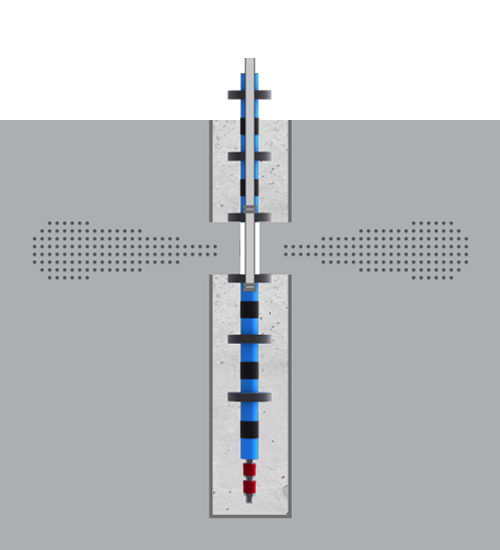

THE STRUCTURE OF THE SLEEVE PIPE

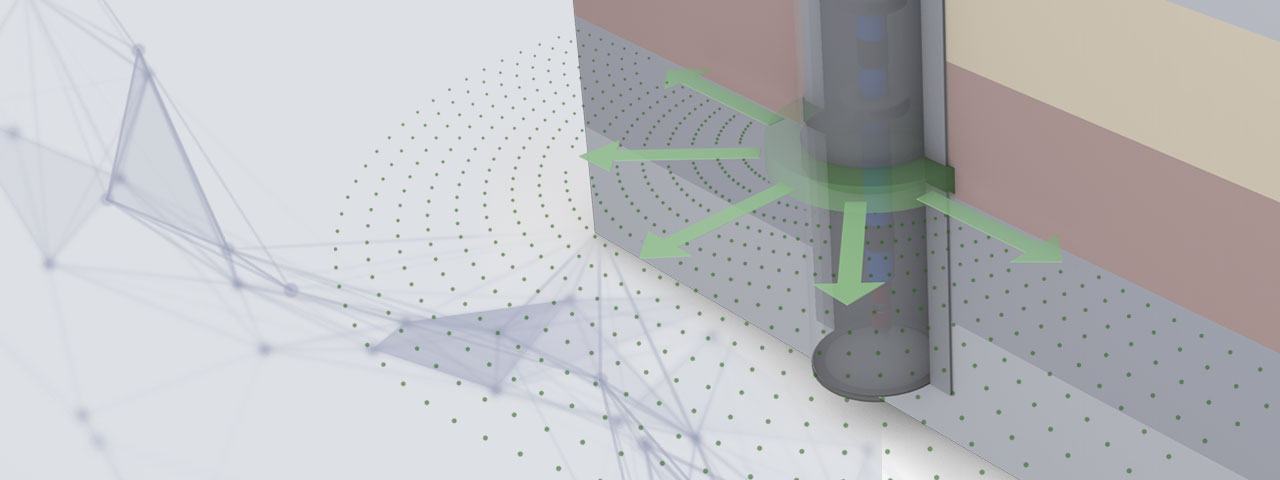

Due to the pressure controlled injection a high horizontal penetration of the oxidizer is achieved with ISCORAPID. It is very effective in low permeable soil zones.

The ISCORAPID procedure

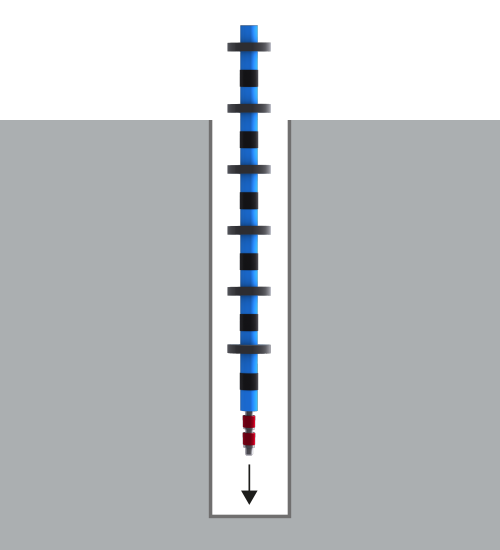

01

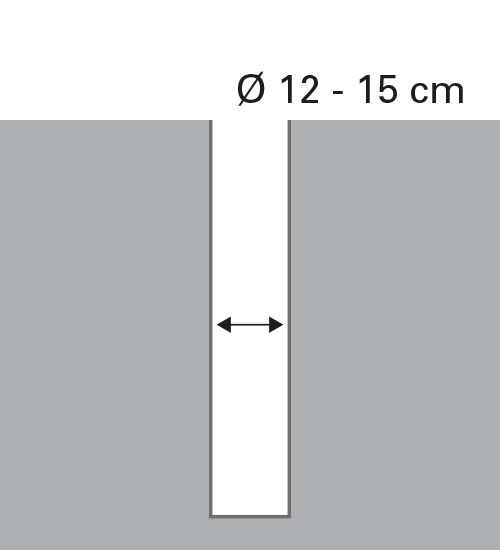

A borehole with the diameter of 5-6 inches is drilled either with auger or core drilling. Casing is only necessary if the soil does not stay open.

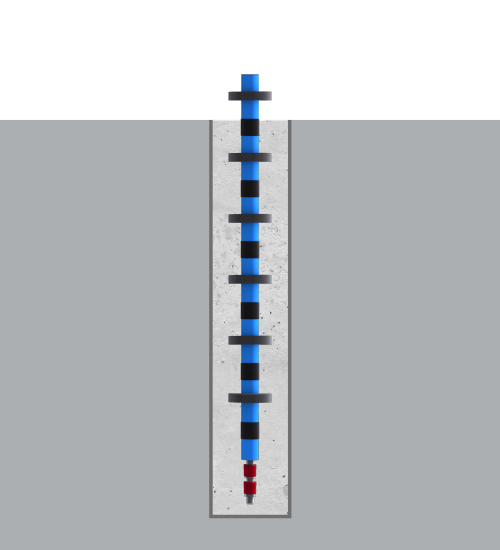

02

Installation of the sleeve pipes. For high depths centralizers will be used to fix the pipe.

03

The annular space is sealed with cement suspension using a tremie pipe. Duration of the cement hardening is 3 days.

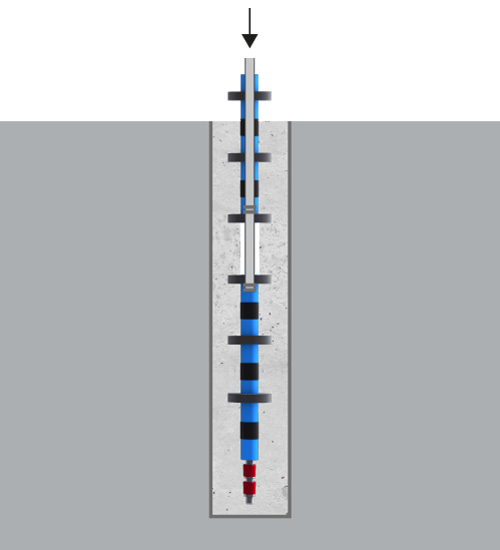

04

After sealing the annular space a double packer is brought into the sleeve pipe.

05

After the cement suspension has hardened, it forms a sheathing around the pipe. This fixes the sleeve pipe in its position and prevents the fluid from rising into the annular space. During injection, the cementation at the perforated areas of the sleeve pipe is broken up by water. The cementation around the pipe is being cracked with a pressure of about 1200 psi (80 bar).

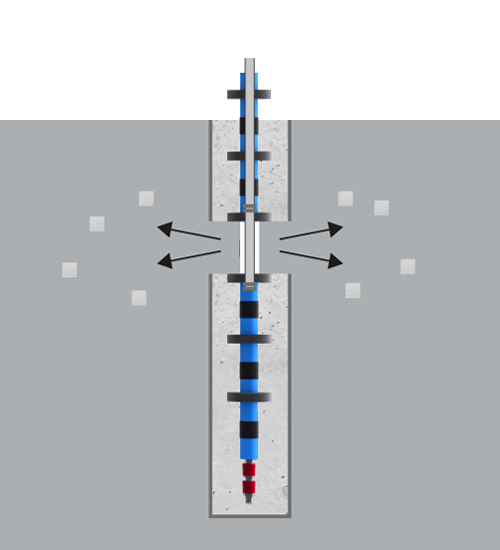

06

After expanding the rubber sleeves the reagent is injected with a pressure of 50 up to 200 psi. The expansion of the double packer’s sealing sleeves can be reversed by reducing the pressure. The packer can be moved within the sleeve pipe so that the injection can be controlled and repeated as many times as required at every sleeve.

ISCORAPID – a patented process

ISCORAPID is a system patented in the European Union and in the United States of America for the in-situ remediation of contaminated soils. You can download the patent specifications here.

European patent specification EP 3 383 559 B1

United States Patent US 10,065,223 B2