THE BEST OF BOTH WORLDS

ISCO

ISCO is accomplished by injecting strong chemical oxidizers directly into contaminated soil or groundwater to destroy chemical contaminants in place. In ISCO, oxidizing compounds are used to decompose the contaminants into harmless compounds like carbon dioxide or water.

The key benefit for ISCO is the fast degradation of targeted contaminants. Compared to pump and treat methods ISCO therefore has a much shorter remedial timeline. Also permanently installed remediation units are not necessary which makes ISCO space-saving.

The primary disadvantage of conventional ISCO: chemical oxidizers are applied randomly into the ground in an uncontrolled manner. This procedure is generally not suitable for unsaturated soil zones.

Foundation Engineering

By using sleeve injection pipes typically applied in foundation engineering ISCORAPID makes up for the disadvantages. The sleeve pipe injection procedure allows grouting of different substances at specific vertical offsets. It is used to improve mechanical properties or to seal and compact loose soil formations or fractured rock.

Injections into contaminated zones can be made precisely and with controlled pressure. Hence, oxidizers penetrate both rock and soils with low permeability. They get directly into contact with the contaminant and facilitate chemical reaction even in micro-fine structures.

Comparison Pump & Treat, ISCO and ISCORAPID

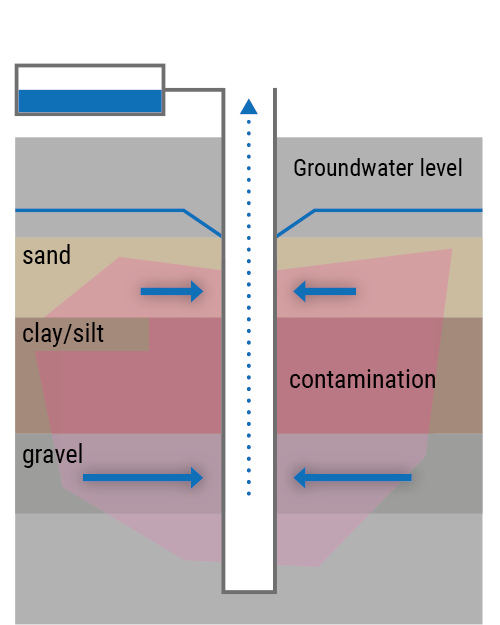

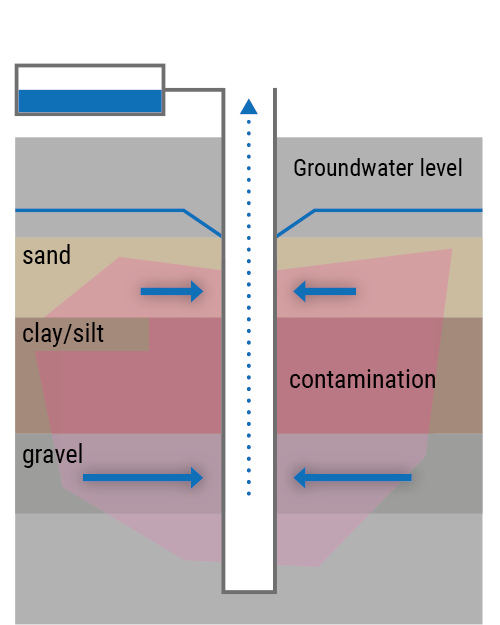

PUMP & TREAT

Hydraulic groundwater extraction with wells and drainages. Deployment of on-site facilities for groundwater purification.

- Groundwater extraction is limited in silt or clay

- more space needed

- only for highly permeable soils

- very long remediation timelines

- cost-intensive, difficult to schedule

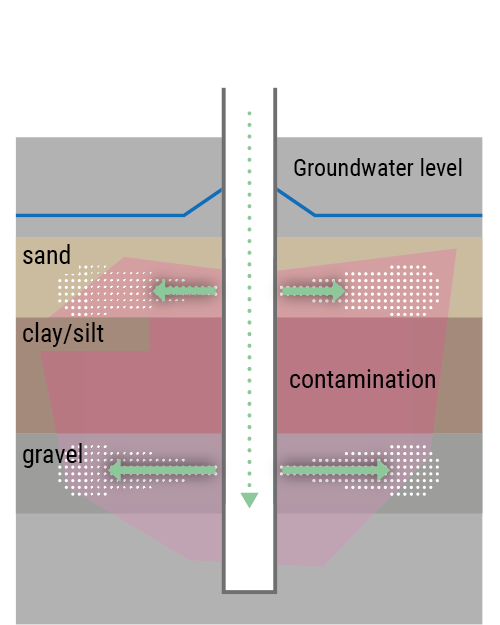

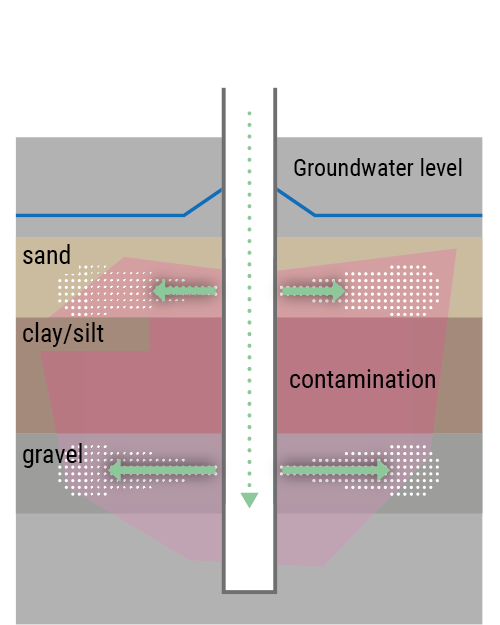

ISCO

Injecting strong chemical oxidizers directly into the contaminated medium (soil or groundwater) to destroy chemical contaminants in situ.

- Radial effect not controllable

- no groundwater extraction necessary, less space needed

- only for highly permeable soils

- reduced remediation timelines

- lower costs

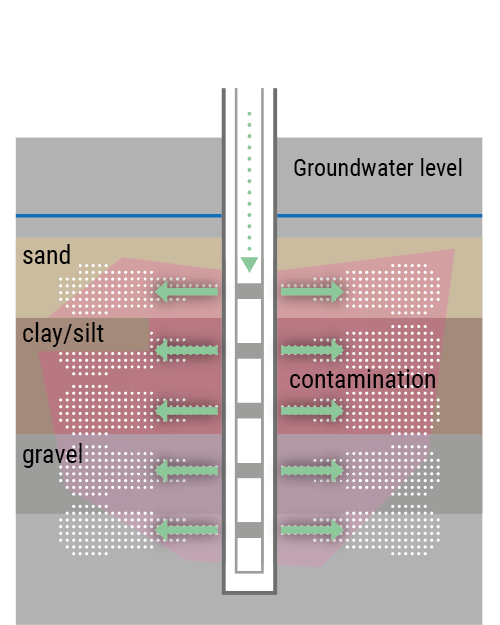

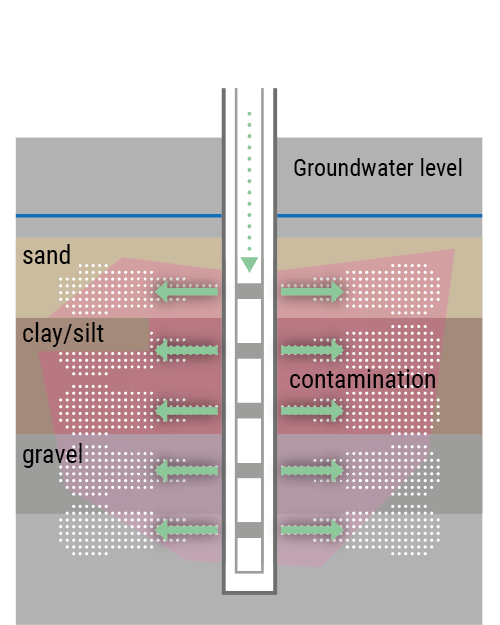

ISCORAPID

Pressure controlled and targeted injection of chemical oxidizers directly into the contaminated ground. Contaminants are destroyed in all soil zones.

- faster remedial success by using pressure

- no groundwater extraction necessary, less space needed

- applicable to almost all subsoil types and conditions

- short timelines, remedial actions can be better scheduled

- lower costs, more accurate budgets

- Contaminants are destroyed in all soil zones

PUMP & TREAT

Hydraulic groundwater extraction with wells and drainages. Deployment of on-site facilities for groundwater purification.

- Groundwater extraction is limited in silt or clay

- more space needed

- only for highly permeable soils

- very long remediation timelines

- cost-intensive, difficult to schedule

ISCO

Injecting strong chemical oxidizers directly into the contaminated medium (soil or groundwater) to destroy chemical contaminants in situ.

- Radial effect not controllable

- no groundwater extraction necessary, less space needed

- only for highly permeable soils

- reduced remediation timelines

- lower costs

ISCORAPID

Pressure controlled and targeted injection of chemical oxidizers directly into the contaminated ground. Contaminants are destroyed in all soil zones.

- faster remedial success by using pressure

- no groundwater extraction necessary, less space needed

- applicable to almost all subsoil types and conditions

- short timelines, remedial actions can be better scheduled

- lower costs, more accurate budgets

- Contaminants are destroyed in all soil zones